Description

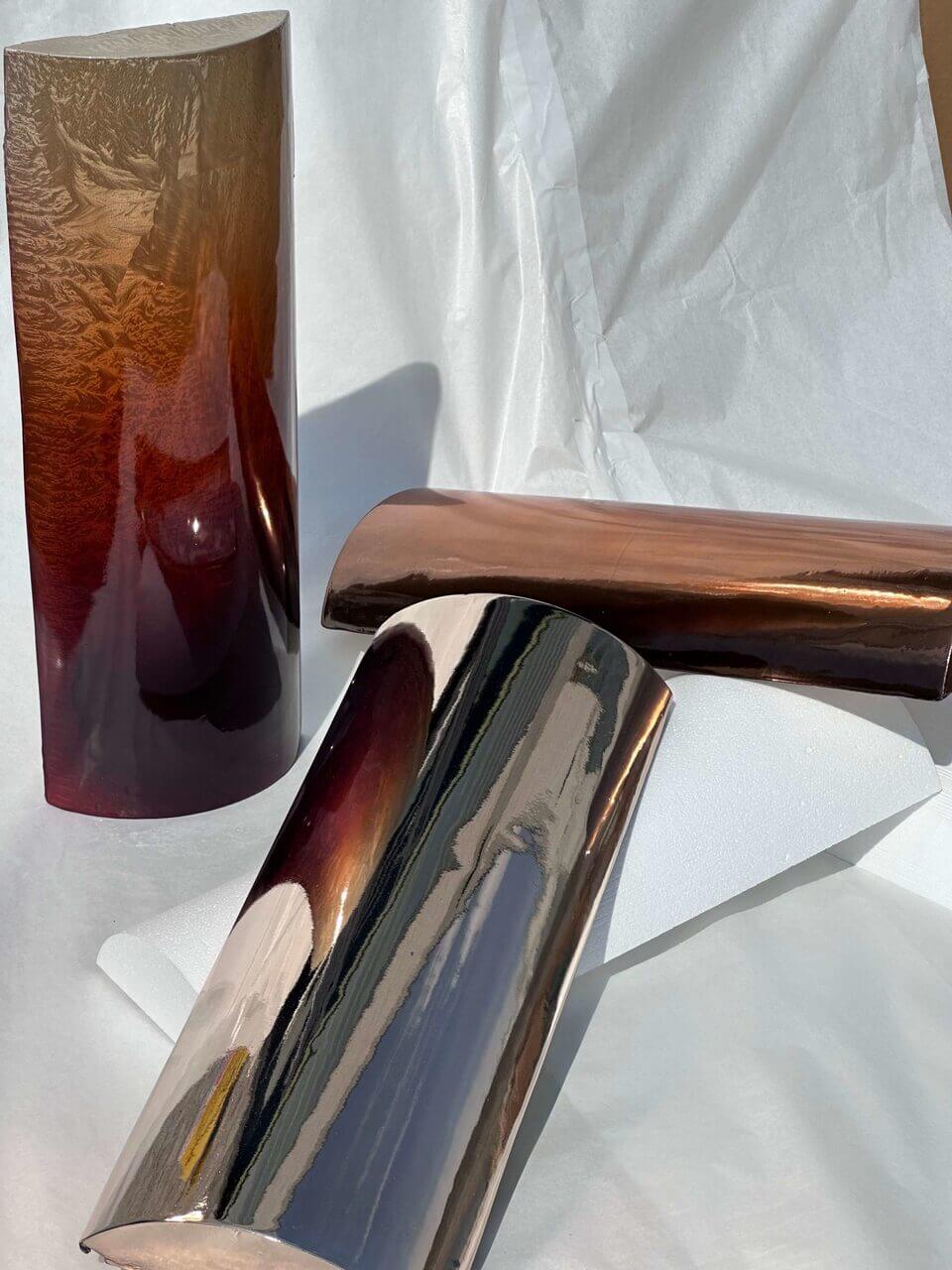

SCUDOCHROMAME 101FB™ – Structural Resilience, Stylish Finish

Elevate your structural and load-bearing applications with SCUDOCHROMAME 101FB™. This epoxy resin boasts exceptional durability and tensile strength, making it a reliable choice for surfaces that endure significant wear and tear. With a unique ability to adhere seamlessly to Styrofoam and terracotta, SCUDOCHROMAME 101FB™ creates a high-gloss, incredibly hard surface without altering the underlying geometry. What’s more, its compatibility with the TUTTOCHROMAME Chroming system ensures a brilliant chrome finish without the need for special preparatory primers. Choose SCUDOCHROMAME 101FB™ for a combination of strength, style, and simplicity in surface enhancement.

Key Features:

– High durability and tensile strength for structural and load-bearing applications.

– Excellent application on Styrofoam and terracotta without altering surface geometry.

– High-gloss, very hard surface.

– Compatibility with TUTTOCHROMAME Chroming system for a seamless chrome finish.