Welcome to the future of marine vessel protection with the Scudo Anti Fouling - Series 8. This groundbreaking product line is meticulously designed to redefine anti-fouling coatings in the marine industry, offering shipowners and operators a unique blend of performance enhancement and environmental sustainability.

The Scudo Anti Fouling - Series 8: A New Era of Marine Protection

Comprising four distinct products, each tailored to specific marine applications, the ScudoChroma Series heralds a new era in marine vessel care. It is the go-to choice for those seeking unparalleled protection against fouling while minimizing the environmental footprint.

Innovative Products:

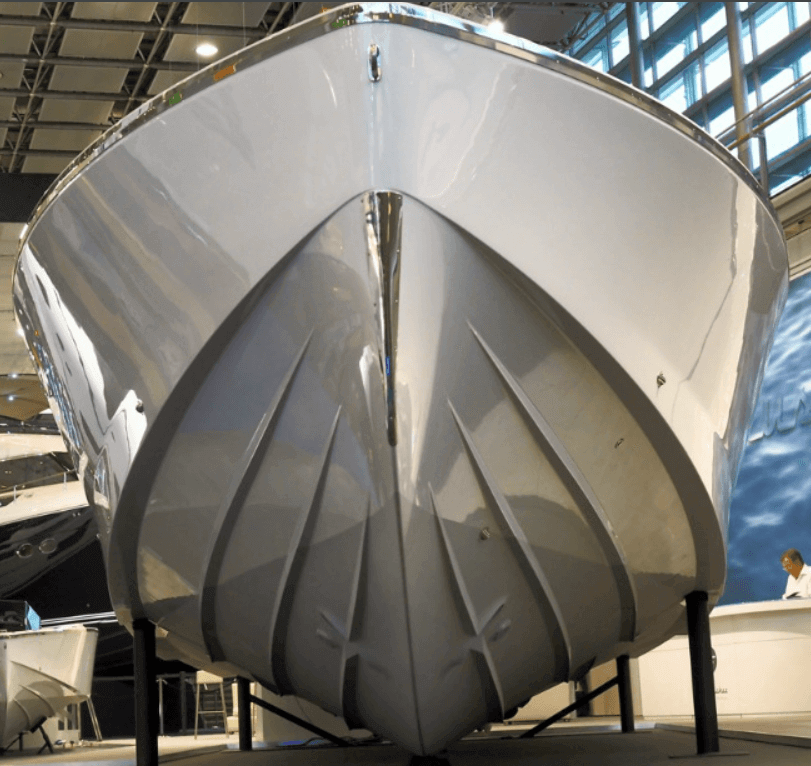

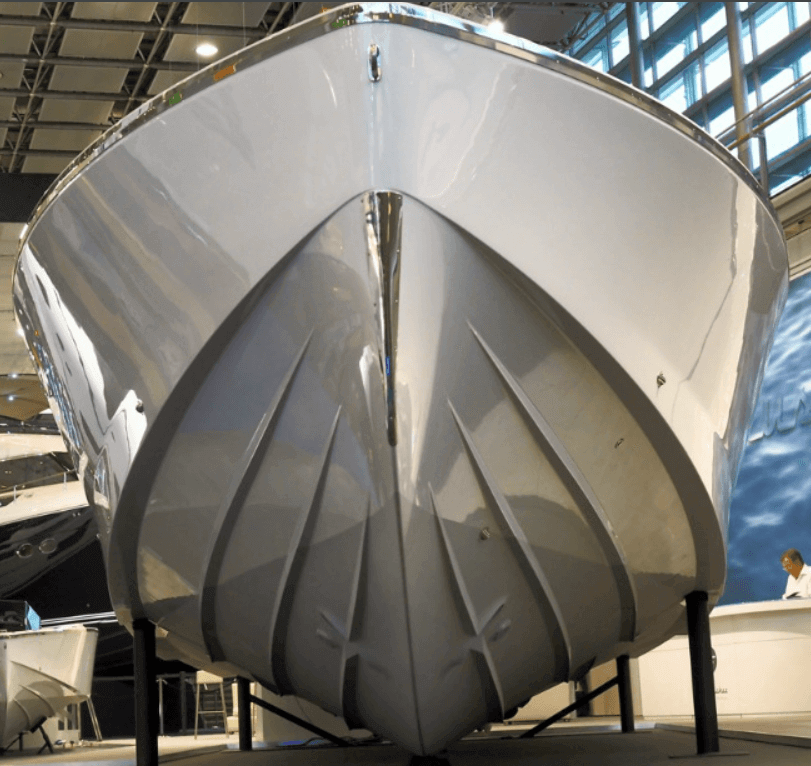

1. ScudoChromaMe™ 102AF - Hull Top:

- Specifically designed for hulls, this product prevents fouling on the main body of the vessel, safeguarding it from the accumulation of marine organisms such as barnacles and algae.

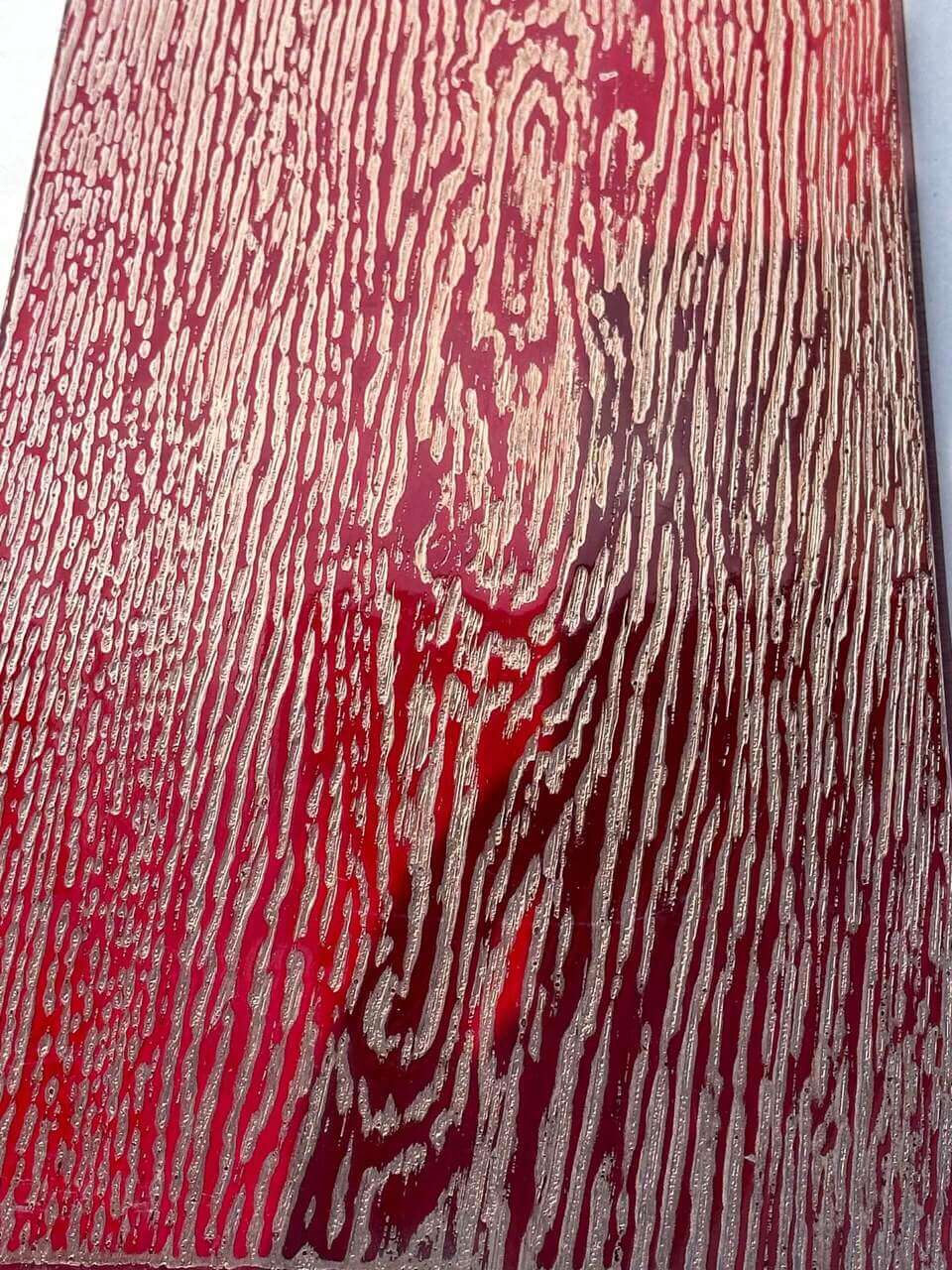

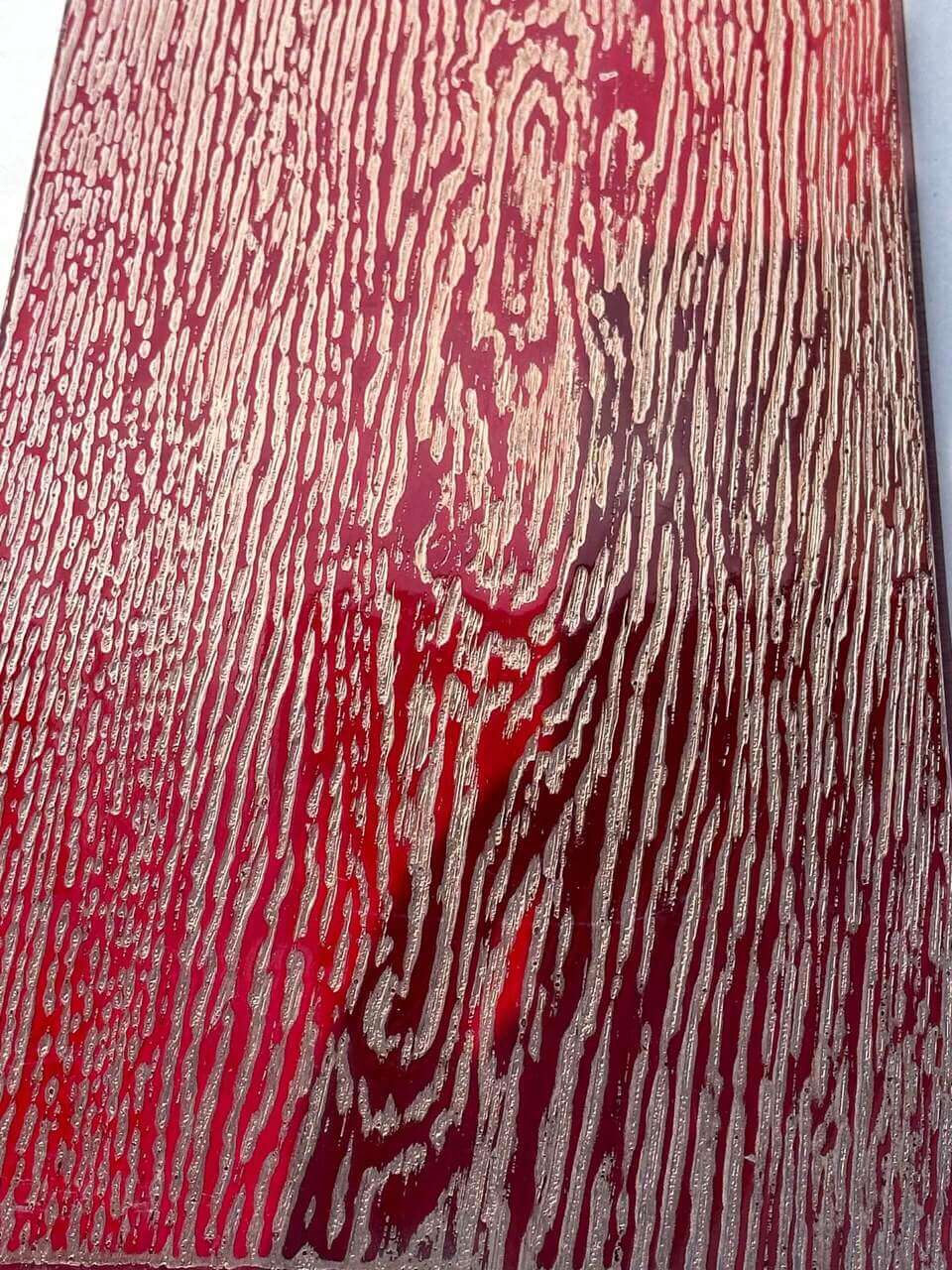

2. ScudoChromaMe™ 502MT - Metal Top:

- Formulated for metal surfaces, this product is ideal for preventing fouling on metal parts of the vessel, ensuring the longevity and efficiency of critical components.

3. ScudoChromaMe™ 602FX - Flex Top:

- Tailored for flexible surfaces, this product offers protection on parts that experience movement, contributing to enhanced durability in dynamic marine environments.

4. ScudoChromaMe™ 402PP - Propeller Top:

- Specifically crafted for propellers, this product safeguards a crucial component prone to fouling, ensuring optimal performance and efficiency.

Advantages of ScudoChroma Series:

- Biocide-free formulation, free from TBT and copper compounds.

- Self-polishing/cleaning for consistent efficacy.

- High abrasion and chemical resistance, ensuring longevity.

- Anti-corrosion protection against saltwater and salt spray.

- Omni-phobic and hydrophobic properties for added resilience.

- Easy application by spray gun on a finely primerized smooth base surface.

- Significantly reduces the need for frequent rehauling and dry dock inspections.

- Extended maintenance intervals, minimizing operational disruptions.

For use on surfaces: